| | |

There are quite a few Mild Steel header flange designs to pick from on this page. In fact, so many choices that the selection process might be confusing and may be even disturbing. Don't worry about this. Once you figure out the basics of what you want to accomplish and are ready to place an order, we'll help you select the best header flange design for your headers.

(Stainless Steel header flanges

are not available at this time.) |

| |

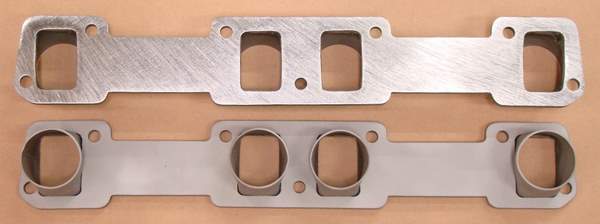

1 3/4" OD Finished Header Flanges - 3/8" thick

1967-76 400-430-455" Buick

(Part Number 20140E38). Also available with 1 5/8", 1 7/8" and 2" OD

Starter Tubes and flange thicknesses of 1/4", 5/16", and 3/8".

Starter Tubes are approximately 2" long.

1 3/4" OD Finished Header Flanges - 3/8" thick

1957-66 364-401-425" Buick

(Part Number 20101E38). Also available with 1 1/2" and 1 5/8" OD

Starter Tubes and flange thicknesses of 1/4", 5/16", and 3/8".

Starter Tubes are approximately 2" long.

1 1/2" OD Finished Header Flanges - 3/8" thick

1961-63 215" Buick (aluminum V8)

(Part Number 20110C38). Also available with 1 1/4" and 1 3/8" OD

Starter Tubes and flange thicknesses of 1/4", 5/16", and 3/8".

Starter Tubes are approximately 2" long.

This header flange also fits the 61-63 215" Pontiac engine as it is identical to the Buick engine.

This design will NOT fit the 64-67 300-340" heads as the distance

between the two center ports on the later heads is about 1/8" more.

If you have these later heads, look at Part Numbers 20111B38 (1 3/8"),

20111C38 (1 1/2"), and 20111D38 (1 5/8").

This design will NOT fit the 61-63 215" Olds engine as the cylinder heads are different.

We have a different design for the 215" Olds engine.

Stage II Buick V6 Header Flanges.

FINISHED Header Flanges (part numbers start with 20) are Plain Header Flanges that have 2" long tubes custom formed into the ports in the header flange and then TIG (not MIG) welded. The header flange is then ground FLAT to remove any weld beads protruding above the gasket surface plus the ports are internally deburred to remove any weld beads that may remain inside the port. (There are a few tube size and port size combinations that require longer than 2" tubes but these are quite rare.) Header Bolts are included.

We call these flanges FINISHED because they come to you with all forming and grinding operations FINISHED. All you have to do is bolt them to the cylinder heads and start to build the header from the end of the tubes. Note that the formed area in the tubes is usually less than half of their length so they can be trimmed considerably to make the headers narrower near the head.

PLAIN Header Flanges (part numbers start with 25) are simply that - NO starter tubes, NO other work performed. NO header bolts.

HEADER FLANGES w/STARTER Tubes (part numbers start with 22) include Plain Header Flanges, Formed Starter Tubes, and Header Bolts. These are only available for a limited number of tube and port size combinations.

We see other companies intentionally leaving partially ground weld beads ABOVE the header flanges' gasket sealing area and saying that this IMPROVES gasket sealing by having these raised areas dig into the gasket. BUT, we've seen these weld beads end up acting as pivot points that cause the header flange to bend. (As you tighten the header bolts on one side of the remaining weld bead - exerting pressure to pull the header flange IN towards the gasket, the flange on the other side of the weld bead tries to pivot on those welds - tries to move OUT - reducing pressure on the gasket in the process - sometimes actually CREATING a gasket sealing/leakage problem!) Their way of grinding a flange is much faster as they only grind off the TOPS of the weld beads. Our way of grinding is MUCH SLOWER (BUT also MUCH BETTER) as we not only remove ALL of the weld bead above the gasket surface (eliminating any "pivot weld beads"), we also grind FLAT the ENTIRE GASKET SURFACE of the header flange to MAXIMIZE gasket sealing area! |

NOTE: Bypass going to the Home page (which is slow to load) by going directly back to the Header Kits page (or any of the other pages/areas listed above).

| Header Kits | Finished

Header Flanges | Plain

Header Flanges | Header Flanges w/Starter Tubes | Header Gaskets | Notes | Note

Explanations.

(Look at the bottom

HEADER FLANGE COMMENTS

area for more

information.) |

|---|

Engine Description -

Cubic Inch Range

Flange Port Size1, Description | Part

Number | Price2,3 | Part

Number | Price2 | Part

Number | Price2,3 | Part

Number | Price |

|---|

| Photo? | Photo? | Flange Design Comments |

|---|

| 53-56 264-322" | | | | | | | | | | |

53-56 Buick

264-322"

1 1/2", Round | 20100C | $314.502 | 25100C | $146.952 | ------ | ------ | ------ | ------ | 4 | 4 = Finished Flange Port will block port in head. |

| | | |

53-56 Buick

264-322"

1 5/8", Round | 20100D | $314.502 | 25100D | $146.952 | ------ | ------ | ------ | ------ | | |

| | | |

| 57-66 364-401-425" | | | | | | | | | | |

57-66 Buick

364-401-425"

1 5/8", Rectangular | 20101D | $314.502 | 25101D | $146.952 | ------ | ------ | 28101 | $24.35 | | |

| See Photo at top | | |

57-66 Buick

364-401-425"

1 3/4", Rectangular | 20101E | $314.502 | 25101E | $146.952 | 22101E | $186.90 | 28101 | $24.35 | | |

| See Photo at top | | |

| 61-63 215" (aluminum) | | | | | | | | | |

61-63 Buick

215" aluminum

1 1/4", Rectangular | 20110A | $314.502 | 25110A | $146.952 | ------ | ------ | ------ | ------ | 1,2 | |

| See Photo at top | | 61-63 centerline distance between two center ports = 6.03" |

61-63 Buick

215" aluminum

1 3/8", Rectangular | 20110B | $314.502 | 25110B | $146.952 | ------ | ------ | ------ | ------ | 1,2 | |

| See Photo at top | | 61-63 centerline distance between two center ports = 6.03" |

61-63 Buick

215" aluminum

1 1/2", Rectangular | 20110C | $314.502 | 25110C | $146.952 | ------ | ------ | ------ | ------ | 1,2 | |

| See Photo at top | | 61-63 centerline distance between two center ports = 6.03" |

| 64-67 300-340" | | | | | | | | | | |

64-67 Buick

300-340" aluminum

1 3/8", Rectangular | 20111B | $314.502 | 25111B | $146.952 | ------ | ------ | ------ | ------ | 1,2 | Also fits 340" cast iron heads. |

| | | 64-67 centerline distance between two center ports = 6.15" |

64-67 Buick

300-340" aluminum

1 1/2", Rectangular | 20111C | $314.502 | 25111C | $146.952 | ------ | ------ | ------ | ------ | 1,2 | Also fits 340" cast iron heads. |

| | | 64-67 centerline distance between two center ports = 6.15" |

64-67 Buick

300-340" aluminum

1 5/8", Rectangular | 20111D | $314.502 | 25111D | $146.952 | ------ | ------ | ------ | ------ | 1,2 | Also fits 340" cast iron heads. |

| | | 64-67 centerline distance between two center ports = 6.15" |

| 196-225-231" V6 | | | | | | | | | | |

62-78 Buick V6

196-225-231"

1 1/4", Rectangular | 20120A | $308.002 | 25120A | $146.952 | ------ | ------ | 28120 | $16.65 | | |

| | | |

62-78 Buick V6

196-225-231"

1 3/8", Rectangular | 20120B | $308.002 | 25120B | $146.952 | ------ | ------ | 28120 | $16.65 | | |

| | | |

62-78 Buick V6

196-225-231"

1 1/2", Rectangular | 20120C | $308.002 | 25120C | $146.952 | ------ | ------ | 28120 | $16.65 | | |

| | | |

62-78 Buick V6

196-225-231"

1 5/8", Rectangular | 20120D | $308.002 | 25120D | $146.952 | ------ | ------ | 28120 | $16.65 | | |

| | | |

79-up Buick

231-252" V6

1 3/8", Rectangular | 20121B | $308.002 | 25121B | $146.952 | ------ | ------ | 28121 | $16.65 | | |

| | | Exhaust ports higher than in 62-78 heads. |

79-up Buick

231-252" V6

1 1/2", Rectangular | 20121C | $308.002 | 25121C | $146.952 | ------ | ------ | 28121 | $16.65 | | |

| | | Exhaust ports higher than in 62-78 heads. |

79-up Buick

231-252" V6

1 5/8", Rectangular | 20121D | $308.002 | 25121D | $146.952 | ------ | ------ | 28121 | $16.65 | | |

| | | Exhaust ports higher than in 62-78 heads. |

STAGE II Buick V6

231-252"

1 1/2", D-Port | 20130C | $308.002 | 25130C | $146.952 | ------ | ------ | 28130 | $22.55 | 38 | 38 = can't guarantee port match on racing heads. |

| | | |

STAGE II Buick V6

231-252"

1 5/8", D-Port | 20130D | $308.002 | 25130D | $146.952 | ------ | ------ | 28130 | $22.55 | 38 | 38 = can't guarantee port match on racing heads. |

| | |

STAGE II Buick V6

231-252"

1 3/4", D-Port | 20130E | $308.002 | 25130E | $146.952 | ------ | ------ | 28130 | $22.55 | 38 | 38 = can't guarantee port match on racing heads. |

| | | |

STAGE II Buick V6

231-252"

1 3/4", D-Port | ------ | ------ | 25131 | $211.552 | ------ | ------ | 28130 | $22.55 | 7,8,38 | 38 = can't guarantee port match on racing heads. 5/16" thick. |

| | Inner Plates, Match to 20132 & 25132 series Outer flanges |

STAGE II Buick V6

231-252" Outer Plate

1 3/4", Round | 20132E | $299.902 | 25132E | $163.752 | ------ | ------ | 28130 | $22.55 | 7,8,38 | 5/16" thick. |

| | | Outer Adapter Plates, Match to 25131/25134 Inner Plates |

STAGE II Buick V6

231-252" Outer Plate

1 7/8", Round | 20132F | $299.902 | 25132F | $163.752 | ------ | ------ | 28130 | $22.55 | 7,8,38 | 5/16" thick. |

| | | Outer Adapter Plates, Match to 25131/25134 Inner Plates |

STAGE II Buick V6

231-252" Outer Plate

2", Round | 20132G | $299.902 | 25132G | $163.752 | ------ | ------ | 28130 | $22.55 | 7,8,38 | 5/16" thick. |

| | | Outer Adapter Plates, Match to 25131/25134 Inner Plates |

STAGE II Buick V6

231-252" Outer Plate

2 1/8", Round | 20132H | $299.902 | 25132H | $163.752 | ------ | ------ | 28130 | $22.55 | 7,8,38 | 5/16" thick. |

| | | Outer Adapter Plates, Match to 25131/25134 Inner Plates |

STAGE II Buick V6

231-252" Aluminum

1 1/2", Rectangular | 20133C | $308.002 | 25133C | $146.952 | ------ | ------ | ------ | ------ | 38 | 38 = can't guarantee port match on racing heads |

| | | |

STAGE II Buick V6

231-252" Aluminum

1 5/8", Rectangular | 20133D | $308.002 | 25133D | $146.952 | ------ | ------ | ------ | ------ | 38 | 38 = can't guarantee port match on racing heads |

| | | |

STAGE II Buick V6

231-252" Aluminum

1 3/4", Rectangular | 20133E | $308.002 | 25133E | $146.952 | ------ | ------ | ------ | ------ | 38 | 38 = can't guarantee port match on racing heads |

| | | |

STAGE II Buick V6

231-252" Aluminum

1 7/8", Rectangular | 20133F | $308.002 | 25133F | $146.952 | ------ | ------ | ------ | ------ | 38 | 38 = can't guarantee port match on racing heads |

| | | |

STAGE II Buick V6

231-252" Aluminum

1 3/4", Rectangular | ------ | ------ | 25134 | $211.552 | ------ | ------ | ------ | ------ | 7,8,38 | 38 = can't guarantee port match on racing heads. 5/16" thick. |

| | | Inner Plates, Match to 20132 & 25132 series Outer flanges |

| 67-76 400-430-455" | | | | | | | | | | |

67-76 Buick

400-430-455"

1 5/8", Rectangular | 20140D | $314.502 | 25140D | $146.952 | ------ | ------ | 28140 | $17.55 | | |

| See Photo at top | | |

67-76 Buick

400-430-455"

1 3/4", Rectangular | 20140E | $314.502 | 25140E | $146.952 | ------ | ------ | 28140 | $17.55 | | |

| See Photo at top | | |

67-76 Buick

400-430-455"

1 7/8", Rectangular | 20140F | $314.502 | 25140F | $146.952 | ------ | ------ | 28140 | $17.55 | | |

| See Photo at top | | |

67-76 Buick

400-430-455"

2", Rectangular | 20140G | $314.502 | 25140G | $146.952 | ------ | ------ | 28140 | $17.55 | | |

| See Photo at top | | |

67-76 Buick

TA brand Stage II 455

2", Round | 20141G | $314.502 | 25141G | $146.952 | ------ | ------ | ------ | ------ | 4 | TA Brand

Aluminum head |

| | | One Piece Design makes it much easier to build headers! |

67-76 Buick

TA brand Stage II 455

2 1/8", Round | 20141H | $314.502 | 25141H | $146.952 | ------ | ------ | ------ | ------ | 4 | TA Brand

Aluminum head |

| | | One Piece Design makes it much easier to build headers! |

| 64-67 350" | | | | | | | | | | |

68-80 Buick

350"

1 5/8", Rectangular | 20150D | $314.502 | 25150D | $146.952 | ------ | ------ | 28150 | $17.55 | | |

| | | |

68-80 Buick

350"

1 3/4", Rectangular | 20150E | $314.502 | 25150E | $146.952 | ------ | ------ | 28150 | $17.55 | | |

| | | |

| DART brand aluminum head that fits SB Chev block | | | | | | | |

DART brand - fits

Small Block Chev

1 3/4", Rectangular | 20160E | $314.502 | 25160E | $146.952 | ------ | ------ | ------ | ------ | 5 | Dart Brand

Aluminum Head. |

| | | 10o Rollover Design, evenly spaced exhaust ports |

DART brand - fits

Small Block Chev

1 7/8", Rectangular | 20160F | $314.502 | 25160F | $146.952 | ------ | ------ | ------ | ------ | 5 | Dart Brand

Aluminum Head |

| | | 10o Rollover Design, evenly spaced exhaust ports |

DART brand - fits

Small Block Chev

2", Rectangular | 20160G | $314.502 | 25160G | $146.952 | ------ | ------ | ------ | ------ | 5 | Dart Brand

Aluminum Head |

| | | 10o Rollover Design, evenly spaced exhaust ports |

DART brand - fits

Small Block Chev

2 1/8", Rectangular | 20160H | $314.502 | 25160H | $146.952 | ------ | ------ | ------ | ------ | 5 | Dart Brand

Aluminum Head |

| | | 10o Rollover Design, evenly spaced exhaust ports |

DART brand - fits

Small Block Chev

2 1/4", Rectangular | 20160J | $314.502 | 25160J | $146.952 | ------ | ------ | ------ | ------ | 5 | Dart Brand

Aluminum Head |

| | | 10o Rollover Design, evenly spaced exhaust ports |

| 123456789A12345678 | Header Flange Design Comments and Explanations. | 123456789A12345678 |

CUSTOM HEADER FLANGES: While the above Header Flange Listing is quite comprehensive, because we do so much CUSTOM designing in this area, one must understand that we offer much more. Based on already existing header flange patterns, over the years we have made header flanges: (1) WITHOUT PORTS for customers using the header flanges to seal the exhaust side of the motor or customers machining the exhaust ports in the flanges to match a reshaped/relocated exhaust port; (2) WITHOUT BOLT HOLES because the customer wanted to drill the bolt holes themselves so as to locate the ports in the flange relative to the ports in the cylinder head a certain way; (3) WITH SMALLER than normal exhaust ports because the flanges were going to be used as SPACERS (between a header and a head) to add clearance to a starter, oil filter, etc.; (4) in Finished Header Flanges, WITH PORTS LARGER than normal relative to a tube size so that a smaller tube size header could be built but with a full size exhaust port in the header flange (one that does NOT block exhaust flow out of the head); etc. In some cases these design revisions are done at no charge but where custom drilling is performed (some movement of the bolt pattern relative to the standard location), there is a $15-25 extra charge for the time involved. Where only ONE flange is desired out of a set of two, we charge 75% of the pair price due to the setup time involved just to make the first flange. We do NOT make PURE custom header flanges (i.e. one of a kind designs where only one or two pieces are needed) due to the development time involved. Header Flanges are made from Mild Steel Plate - NOT available in Stainless Steel.

1 Port Size: ROUND PORTS: This is the Inside Diameter of the ports in the header flange measured in inches. ON ALL OTHER PORT SHAPES: This is the OD of the header tube measured in inches that, when reshaped, would fit into this port size. In other words, this dimension does not truly relate to the size of the port in the header flange but more relates to the tube size specified AFTER being reshaped to approximately match the port in the flange. Keep in mind that we make many header flanges with several choices of port sizes. We usually ship the flanges that match the cylinder head port AND the tube size being used as closely as possible. There are reasons to NOT always ship the best match to the cylinder head port but that is usually due to customer requests or specific needs. We always ask about this because we see no sense in blocking the exhaust port unless there is a good reason to do so.

To make header building MUCH easier, we supply the header flange with ports (those shaped other than round) sized about 1/16-1/8" oversize from a perfect match so that the tubes do NOT have to be shaped perfectly to be inserted into the port. Port Shapes:

RD = Round,

OV = Oval,

RE = Rectangular,

SQ = Square,

DD = D-shaped port with flat on bottom in most cases,

SAP = Same Shape(s) As Port(s) in head.

NA = Not Available or Not Applicable

2 Header Flanges are priced as a set which means V8 and V6 sets have two flanges (one for each head). Most other engines have just one flange in a set. There are several exceptions to these rules but, where applicable, they are all noted. Unless specifically mentioned otherwise, all header flanges are 1/4" thick. If you would like thicker header flanges, add $16.00 for 5/16" or $24.00 for 3/8". All thicker header flanges are made to order and delay header parts shipments about 3-5 days.

Made to order Header Flanges and all welded items (Finished Header Flanges, Custom Collectors, parts with Welded Flanges, etc. are NOT returnable.

3 Finished Header Flanges and Header Flanges w/Starter Tubes are shipped with a complete set of header bolts.

NOTE 1: On 61-63 heads the centerline distance between the center two exhaust ports is 6.03", the 64-67 heads are about 6.15". Make sure that you double check which heads you have before ordering because you can't send the header flanges back if you order the wrong ones..

NOTE 2: We don't have header gaskets for this engine but you can use the header gaskets for the 1962-78 V6 Buick engine (you will have to buy 2 sets).

NOTE 4: TA Performance brand head.

NOTE 5: The machined grooves that provide clearance to the sockets used for tightening/loosening the cylinder head bolts are quite close to the bottom of the exhaust ports in this cylinder head. Our rectangular port shape not only matches the ports in the head better, but, unlike round ports (used by some others in their header flanges for this head), does NOT overlap the machined grooves near the bottom of the exhaust port and, therefore, does NOT CREATE exhaust leaks. You won't have exhaust leaks with our rectangular port header flange design.

NOTE 7: Because of problems with building large header tubes on cylinder heads that have insufficient room between their bolt holes, it is has become necessary to make adapter flanges for some engines. INNER Header Flanges have two bolt patterns in them: (1) The stock bolt pattern that is countersunk so that Flathead Allen Bolts can be used to tighten the INNER flange to the cylinder head and (2) A second bolt pattern that is threaded (usually with a 5/16-18 thread) so that the OUTER header flange can be bolted to the INNER flange. The INNER Header flange is usually ported to match the cylinder heads' exhaust ports. The OUTER Header Flange has a round port in it which usually makes the header easier to build. Both flanges are 5/16" thick.

HEADER FLANGE DESIGN DISCLAIMER: On ANY header flange made to match ANY performance/racing factory/aftermarket cylinder head, due to the fact that the manufacturer - at any time and without notice, might reshape and/or relocate exhaust ports and/or relocate spark plugs and/or change the angle of the spark plugs - we can NO LONGER guarantee port alignment nor spark plug socket clearance. If you are using ANY of these "non-production" heads (or have ported heads) and are concerned with possible port misalignment, we will select the best possible header flange to match your exhaust ports IF you send us a tracing of all ports, bolt holes, and surrounding machined edges. (Note that FAXing is not often accurate enough for our needs.) There is a $10.00 labor charge (no discount) for comparing tracings to current flange designs. There is also a custom flange drilling charge of $15.00 when it becomes necessary to relocate the bolt pattern to align ports to the port tracings as accurately as possible - and NOTE that custom drilled header flanges are NOT returnable! Otherwise, should port misalignments occur, grind flange ports where needed. If spark plug or spark plug socket interference occurs, then modify flange as needed.

R0629,M0226_pOK__pfOK__:m

................................................................................................................................................................................................................................................